- By Admin

- 2024/11/22 9:13:08

Plastic Pet Molds & Pet Preform Hot Runner Molds In china

ZSM MOULD manufactures high precision PET Preform Molds, catering to hundreds of satisfied customers at home and abroad.

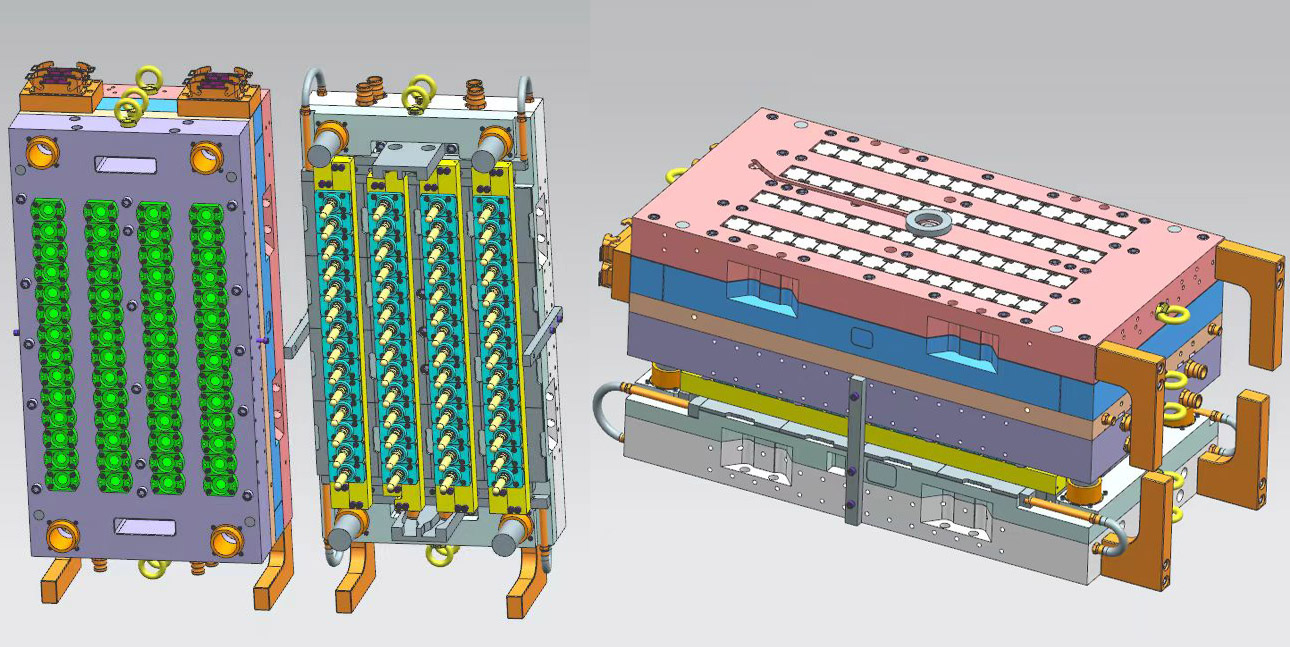

The company has made a mark in the design and development of a wide range of optimized Mold Systems. The company provides Preform Molds up to 72 cavitations, weighing from 4 to 750 grams and in neck sizes from 12 to 150 mm.With successful track record, ZSM continues to support the consumer base in the bottling segment of drinking water, aerated beverages, liquors and spirits, processed syrups and sauces, confectionery, edible oils, pharmaceuticals, cosmetics, shampoos, items of personal care, detergents, pesticides and industrial oils among others.

Salient features of our molds are:

Optimised Preform design of molds to ensure dynamic results in bottle blowing

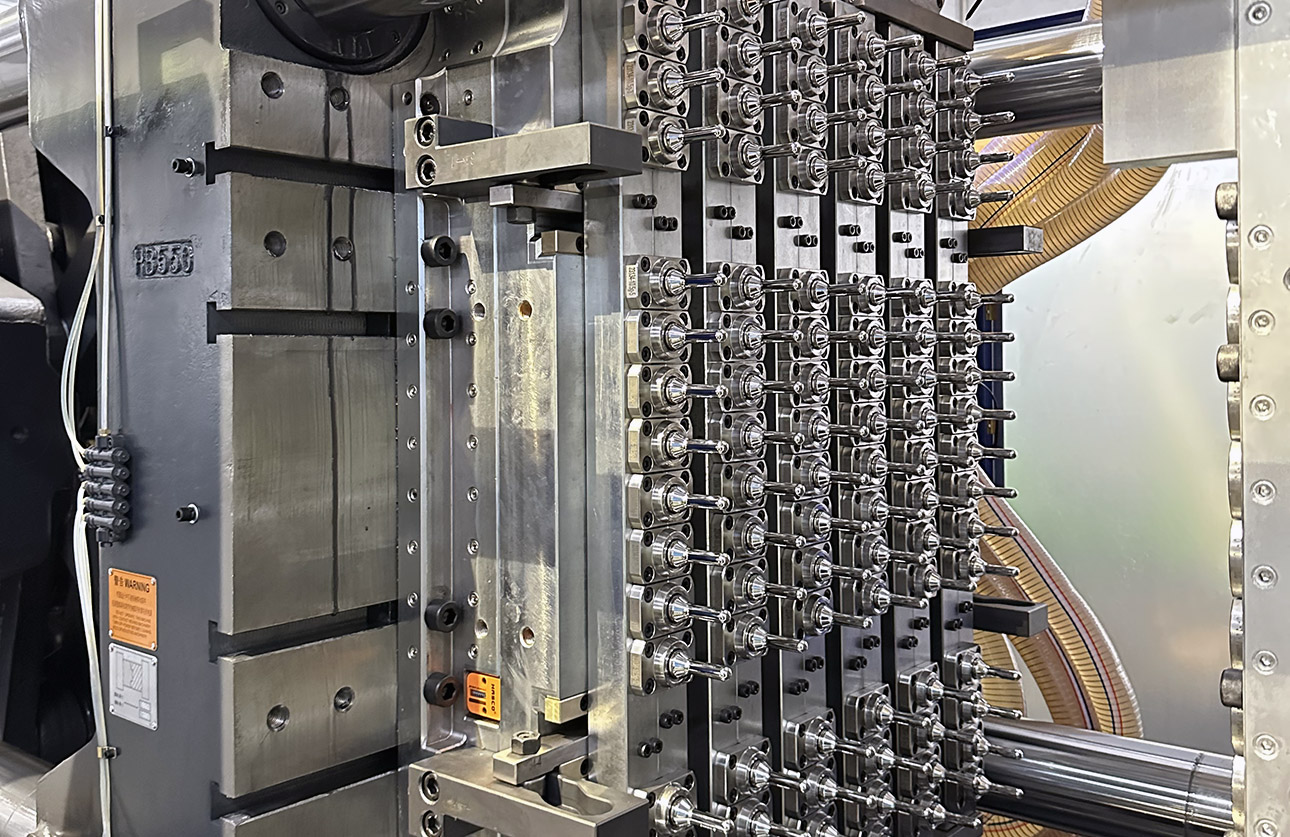

Preform molds with valve gate Hot Runner system

Manufactured in modular concept for standard interchangeable mold components for ease of replacement.

Variation in Preform wall thickness of ±0.10mm, depending on its length

Machining tolerances of the order of 0.005mm (5 microns)

A well-balanced cooling channel layout and turbulent water flow for consistency in cooling and efficient heat transfer

Application of internationally advanced two-step dual taper locating technology

Independent self-locking of each cavity to ensure high concentricity of product

UNIQUE hot runner system utilizing the latest technology combined with the best steel material and highly interchangeable standard parts. These guarantee a good shot-to-shot repetitiveness, drop-to-drop consistency and long usage life of the system. Fully balanced manifold enable a tight tolerance of preform weight and dimensions.

| Product Name: | Plastic bottle blow mold,plastic preform mold |

| Shaping Mode: | Blowing Mould |

| Mould Size: | Customized |

| Product Material: | Steel |

| Product: | water juice cooking oil bottles |

| Mould material: | steel ,stainless steel,alumminum etc |

| Design soft ware: | UG,Pro E solidwork,Auto CAD,Mould flow |

| Mould cavity: | sigle,multi cavity |

| Mould standard parts: | DME.HASCO,ETC |

| Mould surface: | EDM,texture,high gloss polishing |

| Hardness of the steel: | 20-60hrc |

| Plastic material: | PET,PP |

| Inspection: | When mould finished ,we will blow some bottles send to clients check |

| Lead time: | 7-10 weeks |