- By Admin

- 2024/11/25 9:51:49

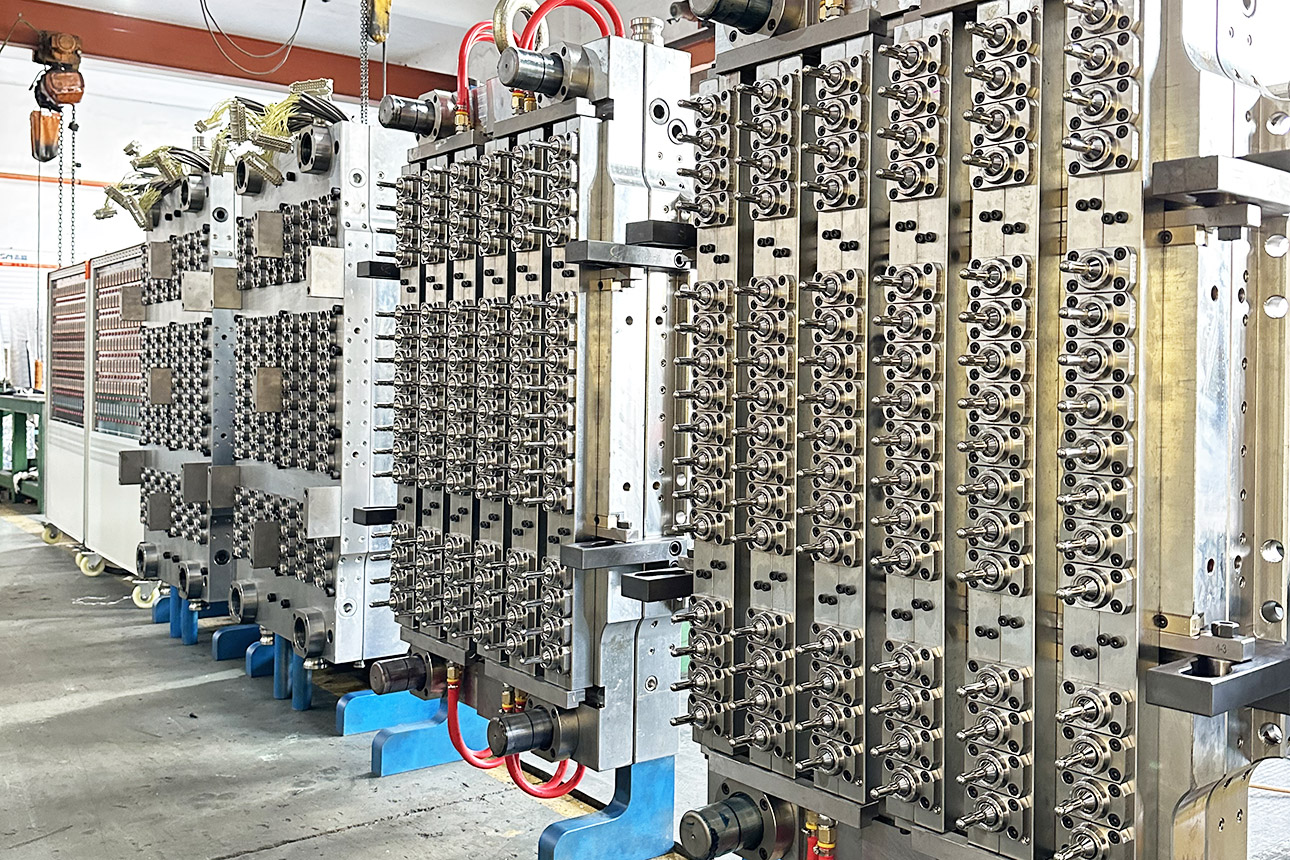

PET Preform Mold Conversion Manufacturer and Supplier

ZSM mold factory, we are professional making cap mold,PET preform mold and cap compression machine. We have a strong R & D team, can design and manufacture 1 cavity to 96 cavity mold, according to customer machine requirements.

PET preform molds are an essential component in the manufacturing of PET preforms, which serve as the building blocks for high-quality plastic bottles. Renowned suppliers in the industry offer a wide range of PET preform molds, incorporating advanced technology, superior design, and precise engineering. These molds are designed to meet the stringent requirements of the packaging industry, delivering exceptional performance and ensuring consistent, reliable results.

Through years of expertise and innovation, ZSM has established itself as leader in the PET preform mold market. ZSM dedicate to excellence, commitment to customer satisfaction, and continuous research and development have positioned them at the forefront of the industry.

NEW MOLDS

1. Dimensioning, such as in interface determination

2. Application and product consultation

3. Mold start-up, to match with proper machines

4. Mold testing when meet problems

MOLD REFURBISHMENTS ALLOWED

Hot halves;Cold halves;Take-out plate and post-mold cooling devices

MOLD CHANGES ALLOWED

Weight changes

Thread changes

Contour changes

Weight optimization

Wall thickness changes

Gate changes

Extra Valuable Service

1. Provide 12 months or 3 million times of the whole mold free warranty service, core components 5 million times warranty;

2. Provide applicable training based on customer needs

3. Provide adequate engineering services personnel to assist rapid production;

4. Provided with one professional service engineer to stay to promote local sales and maintenance

5. Provide one or two free door-to-door comprehensive services every year.

| PET Preform Mould Specification | |

| Mould name | 96 cavity preform mould for PCO 1810 Neck 12.6g Preform |

| Mould cavity | 96 cavity |

| Neck finish | PCO 1810 Neck finish |

| Preform weight | 12.6g |

| Insert materials | ASSAB FS136/Purpose made 632 |

| Mould plate | 4Cr13/P20(Preharden) |

| Hot plate | H13(Preharden) |

| Heating coil | Rotfil from Italy/Hotset from Germany |

| Copper nozzle | Beryllium bronze From Italy |

| Insulator | From USA DU PONT |

| Suitable injection molding machines | Husky, Netstal PET line, PET Master, General PET injection molding machine |